Torque vectoring explained

February 24, 2022 by Ryan Hirons

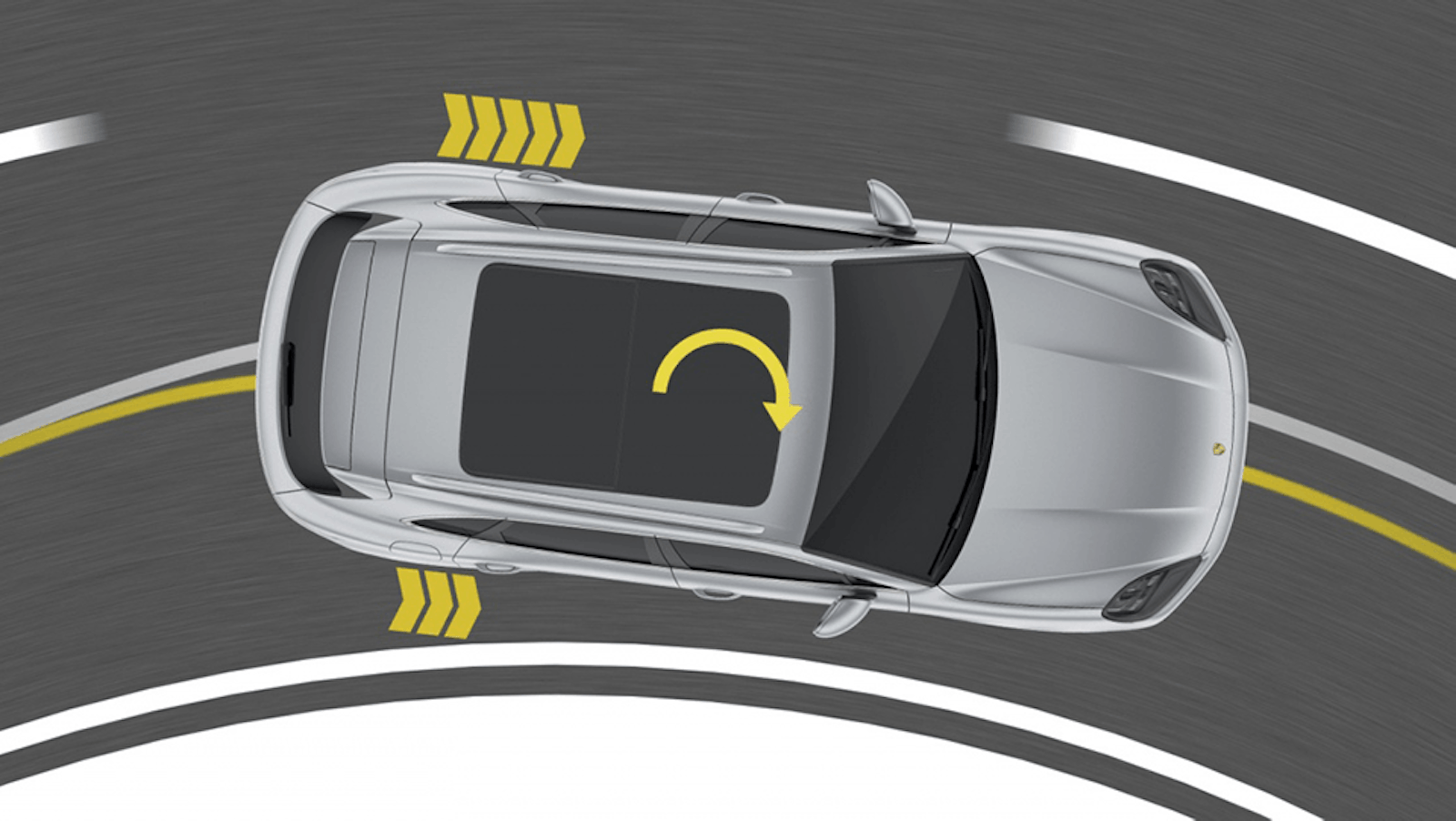

Torque vectoring systems are designed to improve a car’s grip, and when driving quickly or in slippery conditions.

How do these systems work though, and which cars might you find them on? This guide explains.

How does torque-vectoring work?

In simple terms, torque vectoring is a computer-controlled system that controls how much power your car’s engine or motors send to each individual wheel. By controlling power more effectively, a car with torque vectoring will have more grip on slippery surfaces and can accelerate more quickly.

Different torque vectoring systems do this job in different ways. Though all ultimately have the same goal.

Torque vectoring using a differential

A differential (often referred to as a ‘diff’) takes power and torque from the engine and distributes it evenly between the car’s driven wheels.

A normal differential (sometimes called an ‘open’ diff) can’t control which wheel receives the most torque. If one wheel starts to spin (due to ice, water or mud on the road) then the engine’s power will take the path of least resistance, and continue to spin the slipping wheel rather than the one that still has traction.

A torque vectoring system electronically manages how that power is distributed. It does this using small clutches within the differential that precisely control how much torque is sent to each wheel, and therefore how much the wheel is allowed to slip. This will be according to the grip available to the wheels and what the driver’s asking of them.

This differs from a limited-slip differential (LSD), which does a similar job using mechanically controlled systems. An LSD can limit power to a wheel that doesn’t need it, but an electronic system can actively redistribute this power and torque to the wheel with the most grip.

Torque vectoring using brakes

Torque vectoring systems don’t always use a differential, though. In small hot hatches like the Volkswagen Polo GTI for example, it’d be too expensive for its price point and complex to put into such a small space.

In this type of application, torque vectoring through braking can be used. This system works by using the brakes to stop a wheel from slipping.

This allows more power to be sent to the wheels that still have grip, improving a car’s ability to accelerate on slippery roads or accelerate out of tight corners.

What are the pros and cons of torque vectoring?

On the face of it, it seems like having torque vectoring can only be a good thing for your car. While it does have a lot to offer, it’s not entirely perfect.

Pros of torque vectoring

- It’s helpful in slippery conditions

Torque vectoring can help stop you from getting stuck in slippery conditions.

- It’ll improve cornering stability

More grip through the corners means you can take them with confidence.

- It’s good for the track

If you’re going for lap times around a track, torque vectoring will come in handy. It’s no shock the tech was developed in motorsport.

Cons of torque vectoring

- You won’t see a benefit in most driving

Unless you drive down muddy country roads or you drive a car enthusiastically, you won’t really feel the benefit of torque vectoring. As a result, it’s not worth buying a car just for the technology unless you plan to make use of it.

- It’s complicated and expensive

Though a lot of performance cars will come with the tech as standard, torque vectoring can also be an expensive option. If it goes wrong, it’s difficult and expensive to have repaired too.

Which cars have torque vectoring?

Torque vectoring is typically the reserve of high-end performance cars, though some more affordable hot hatches use it too. A handful of examples of cars with torque vectoring include:

- Audi RS 3 (known as RS Torque Splitter) and other RS models

- Ferrari SF90 Stradale

- Hyundai i30 N

- Select Porsche models (known as PTV, usually an option)

- VW Golf R and Polo GTI (known as XDS)

Cars Change? Carwow!

Looking for a new set of wheels? With Carwow you can sell your car quickly and for a fair price – as well as find great offers on your next one. Whether you’re looking to buy a car brand new, are after something used or you want to explore car leasing options, Carwow is your one stop shop for new car deals.